Case Studies

Royal Canadian Navy

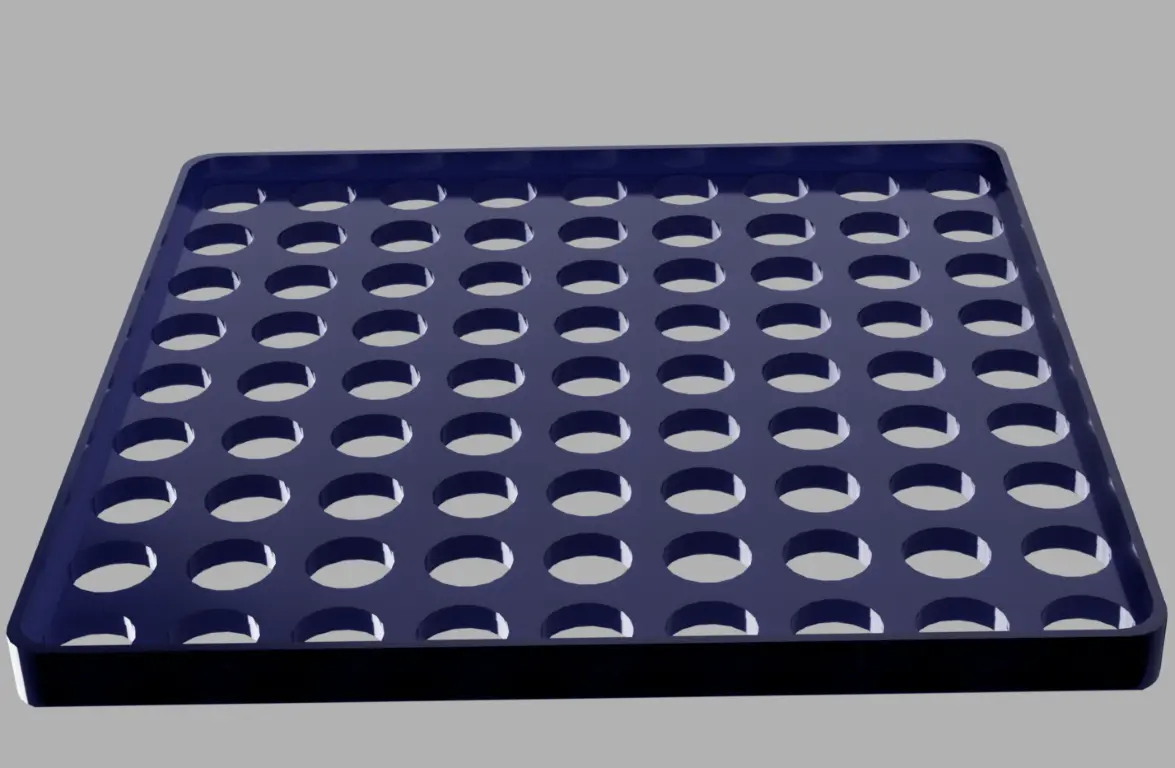

Original parts from the HMCS Regina are starting to degrade, and the original manufacturer went bankrupt years ago. We work with the Canadian Armed Forces to design & create replacement parts designed to last.

We digitally recreated the original parts before modifiying the designs for improved durability. Leveraging our volume production capabilities, we are able to produce large batches of these parts at an extremely competitive price.

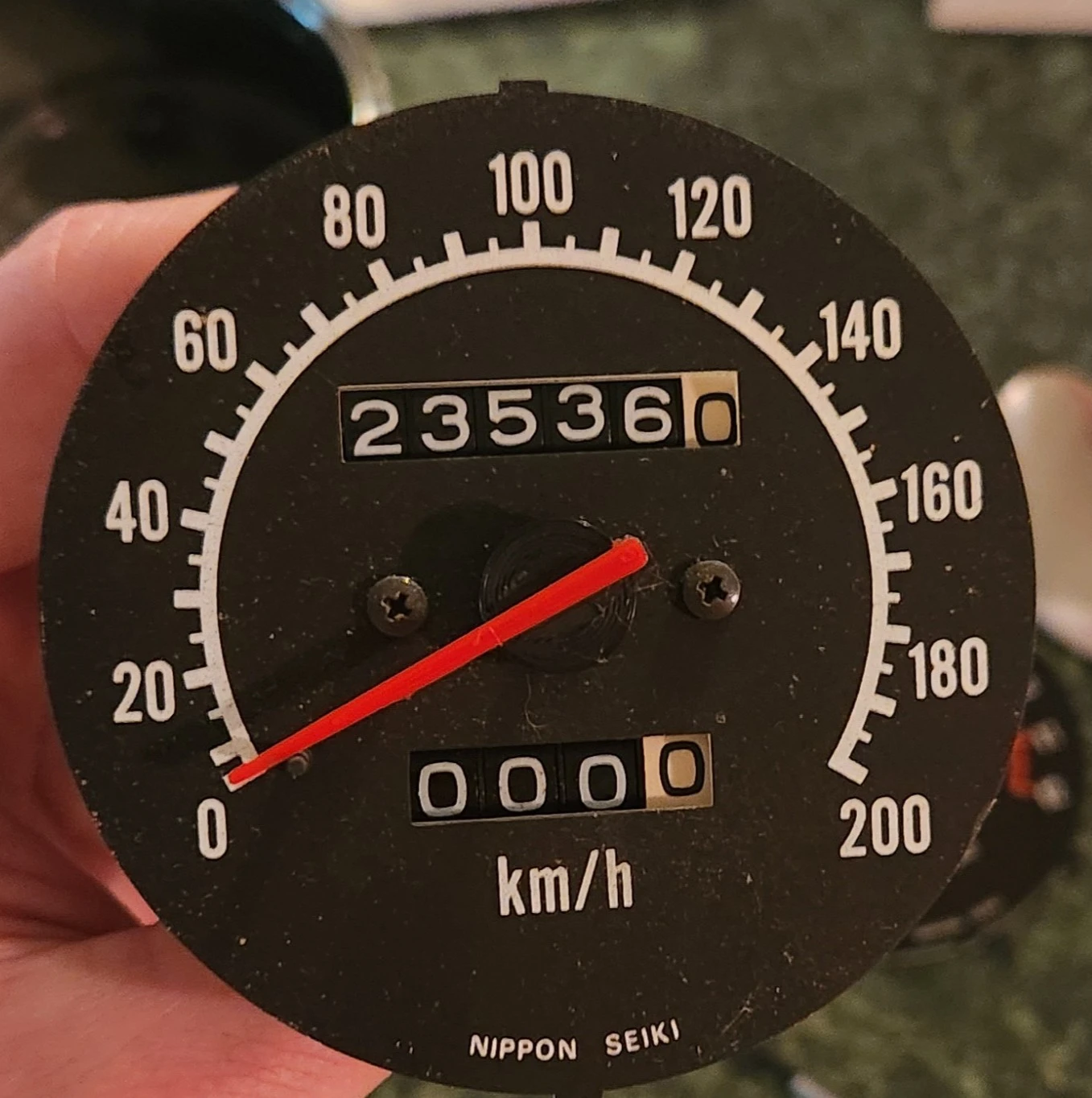

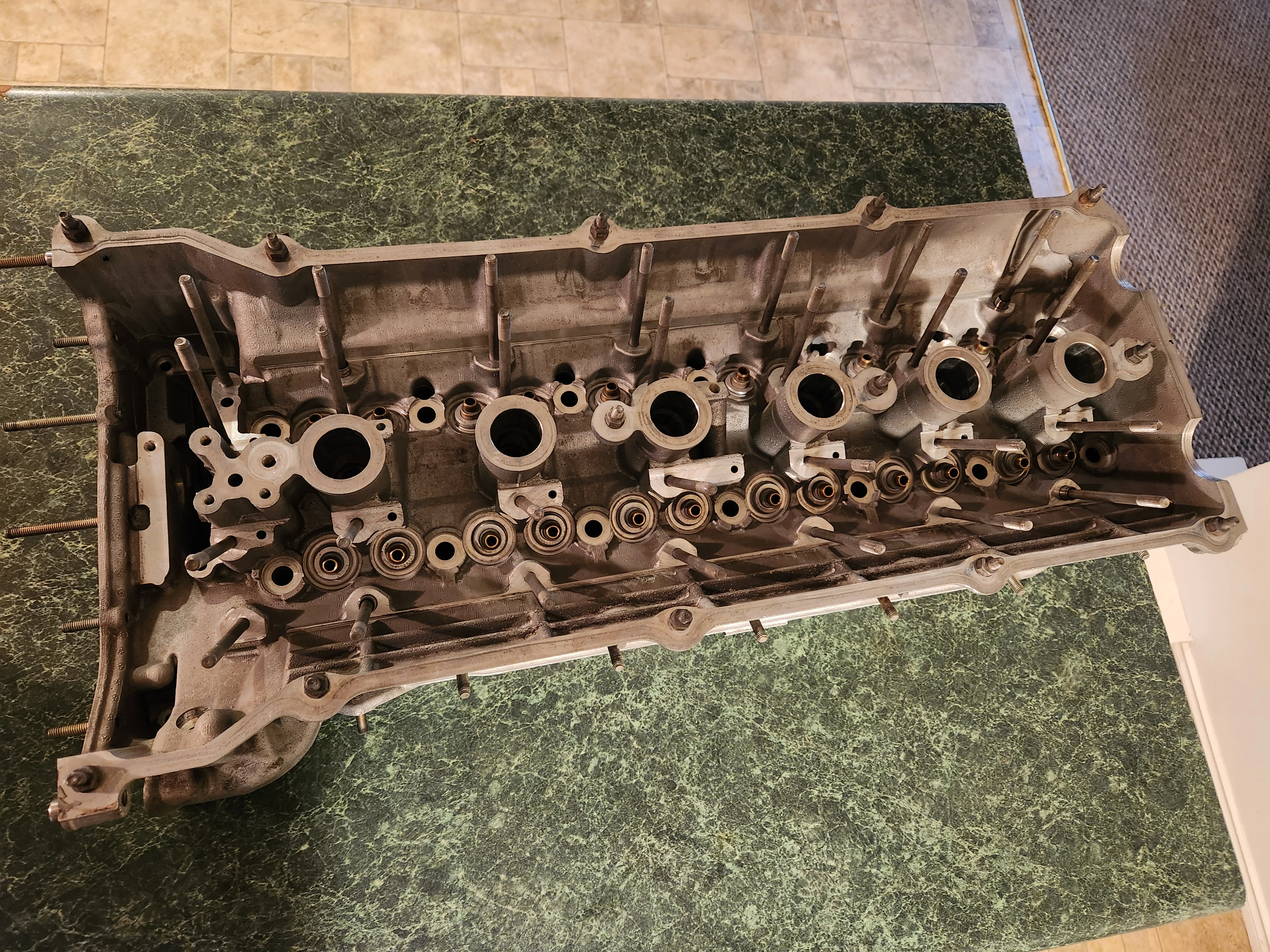

Vintage Car Restoration

Whether it's plastic clips, hubcaps, intake manifolds, or gaskets, vintage car & motorcycle parts can be hard to find. We 3D scan, model, and print new parts for vehicles new and old.

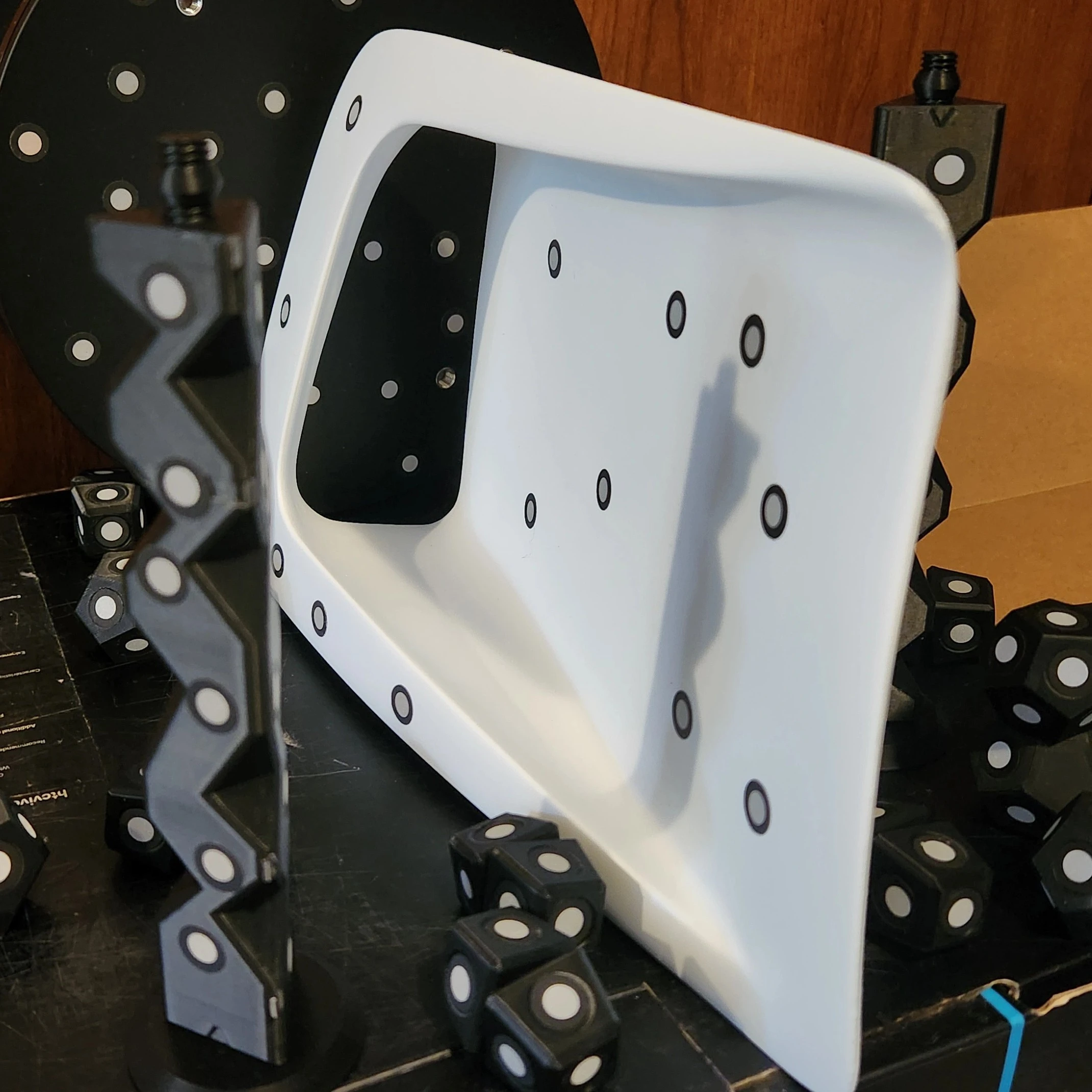

W̱SÁNEĆ Marine Guardians

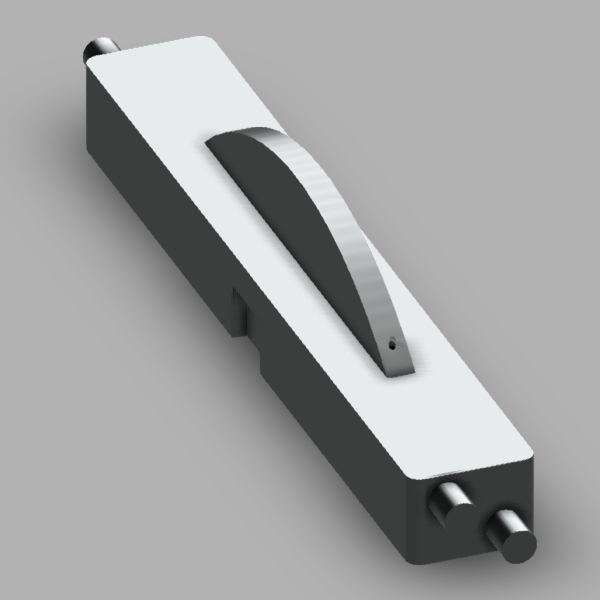

The W̱SÁNEĆ Marine Guardians use a DJI Matrice M30 to perform habitat monitoring for local whale populations. Given its' enormous size it is quite hard to launch and land on a moving boat.

We designed, prototyped, and produced a catch handle to minimize risk to the drone during takeoff and landing. It is specially designed to not obstruct any of the drone's instruments and sensors, while being resilient to ocean conditions. This is a great example of our rapid, in-house product design capacity.

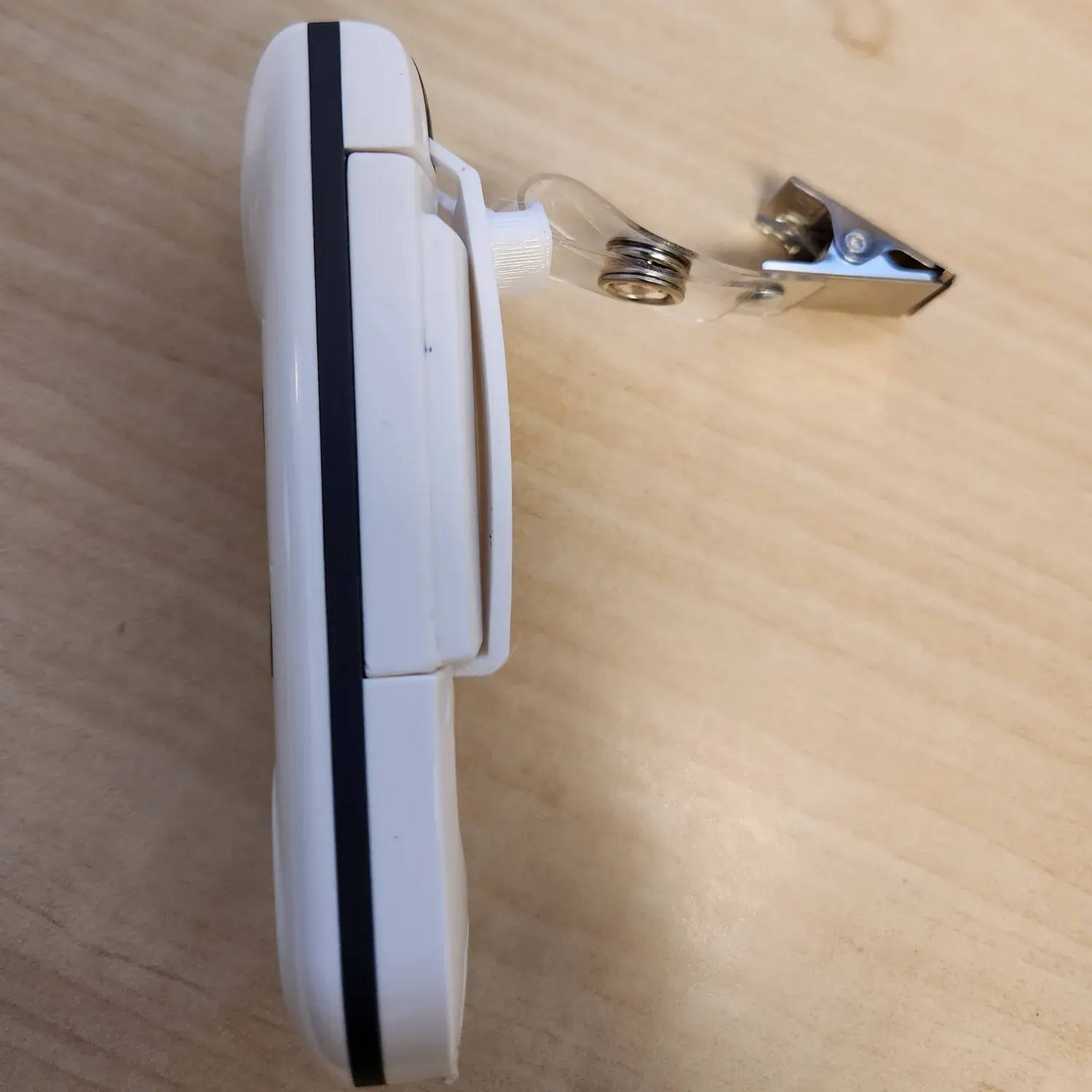

Island Health

Voceras are medical pagers with removable batteries. These batteries have clips that are notorious for breaking off, and replacements are prohibitavely expensive. Island Health operates a fleet of 1000+ devices, and this was a serious issue costing taxpayers $10k+/year.

Working closely with them we designed a solution that would replace the broken clips with a stronger alternative. Initial testing was a huge success, and we now produce these clips for their fleet, saving hundreds of batteries from the landfil each year.

Local Manufacturing

We build jigs, tools, and more for local manufacturing companies to increase their efficiency, lower rejection rates, and build better products.

High Performance Cycling

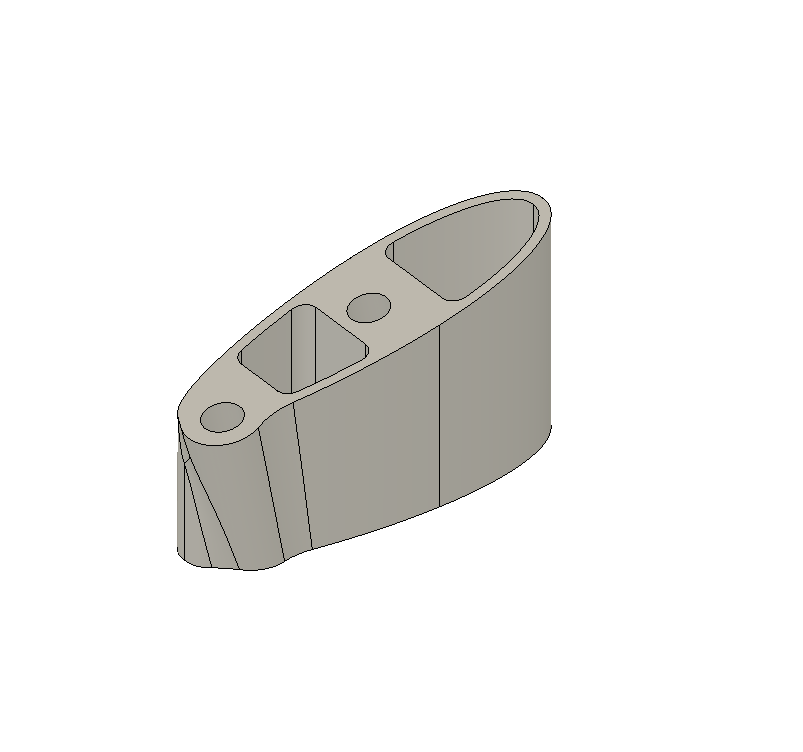

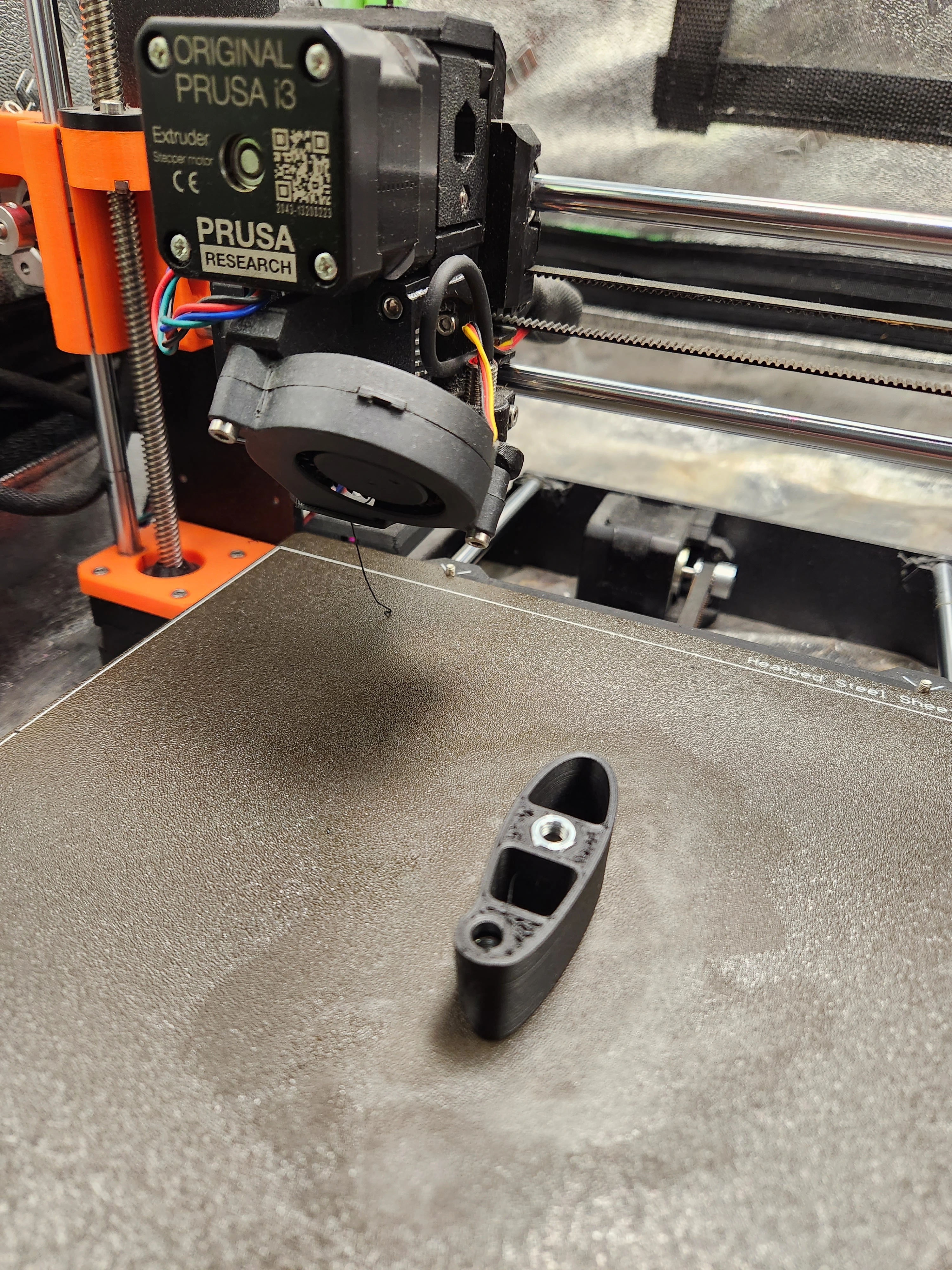

Our client is a high-performance cyclist who wanted to modify his handlebar layout and nothing on the market let him achieve the precise height and angle he needed.

We worked with him to model, prototype, and iterate on a design that perfectly met his needs. The final prototypes were printed in PA-CF with inset nuts, before the final product was machined out of aluminium.